Proper Burial Depths for Subsurface PVC Pipe

How Deep You Bury PVC Depends on a Couple of Factors

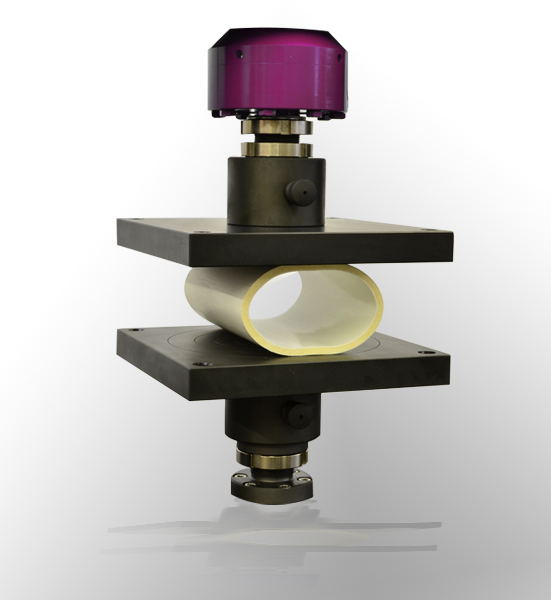

Questions about the maximum burial depth for PVC pipe are often asked by people in the water main detection and pipe detection fields, especially in regards to PVC sewer pipe. Sewer detection involves using GPR or other instrument to map the location of underground piping. The best way to locate underground PVC pipe is with a device called the AML PVC Pipe Detector from SSI Locators. But, what is the maximum depth PVC can be buried? Surprisingly, the pipe isn’t the determining factor. The deciding factors are the quality of the embedment material and installation of the buried PVC pipe.

The AML PVC pipe detector uses ultra-high radio frequencies to find subsurface PVC pipe. Locating buried PVC pipe is complicated, so it requires a unique process. The AML is a patented scientific instrument that changes the way people locate PVC pipes, or nearly any subsurface object with an edge. The technology was originally developed for use in lunar exploration, but SSI Locators has exclusive ownership of this specific type of PVC pipe detector. The AML can find nearly any subsurface material, so it functions well as a buried cable locator and gas pipe locator also. The following information describes the main factors to consider when determining proper burial depth for an underground PVC pipe.

Flexible Conduit Versus Rigid Conduit

PVC piping has been classified as a flexible conduit. Ductile iron pipe, which supersedes cast iron piping, is also classified as a flexible conduit, while clay and concrete pipe have been classified as rigid conduits. The difference between rigid and flexible conduit is fairly obvious. Flexible conduit can bend under the pressure of traffic loads and soil without breaking. As the weight shifts or increases, flexible conduit reacts by deflecting vertically and extending horizontally. The weight of the soil and traffic above the conduit is dispersed into the embedment material against the sides of the buried pipe. Rigid conduits, on the other hand, must rely on structural strength to resist the heavy loads. If the rigid conduit reaches a maximum load, it can break under the pressure. If you work in water main detection or sewer detection, you have most likely have heard the term “crush rating” or “crush strength”. This refers to the maximum weight the conduit can bear without failing. Since flexible conduit reacts differently under a heavy weight load, the term “crush strength” doesn’t apply to PVC pipe.

If you are a regular user of a PVC pipe locator, you will know that PVC pipe itself can’t support very much weight before deflecting, or beginning to curve under pressure. An underground electrical locator will still find pipe that is deflecting under the load weight it is bearing. To avoid failure from flexing too much, PVC pipe is almost totally reliant on the quality and compaction of the surrounding embedment material. The more compacted it is, the more the pipe is supported by the embedment material. Someone who works in the subsurface industries as a wire locator or gas pipe locator should know the equation for figuring the maximum deflection of a specific flexible conduit. PVC pipe detection can be difficult, so the more you understand deflection versus crush strength, the better off you will be.

Pipe Deflection Calculations

Using a PVC pipe detector or pipe locator like the AML PVC Pipe Detector may require you to calculate pipe deflection. Many factors weigh in when determining pipe deflection before using a pipe locator. These include the stiffness of the pipe, pipe wall thickness, stiffness of the surrounding embedment and the techniques the contractor used for burying the pipe. The calculated values are independent of the pipe’s size since the pipe stiffness value remains the same for all. A pipe detector finds the underground object, but it’s up to the contractor to determine deflection before installing the pipe, using a quality embedment to support the load on the piping. Although an underground electrical locator can map out a pipe’s location, it can’t repair a pipe that’s approaching maximum deflection.

Overall traffic loads can also be incorporated into these calculations. These are a much bigger issue with shallow burials than with deeper ones. At depths of more than 10 feet, a water traffic load is often considered to have a little to no effect on the buried pipe. 12″ from the top of the pipe to the underside of the road surface is the minimum depth at which PVC pipe with traffic loading can be buried. Pay close attention to the placement, selection and compaction of flexible pipes at shallow depths below rigid road surfaces. This will prevent excessive cracking of the road’s surface.

By combining the proper soil stiffness and pipe stiffness, PVC pipe of all sizes can be used at significant depths, very efficiently and economically by using proper installation techniques. The best PVC pipe detector on today’s market is the AML PVC Pipe Detector. Its patented ultra-high radiowaves frequencies can locate almost any type of buried object through most surfaces. It finds both metallic and non-metallic objects underground, so it makes a great PVC pipe locator as well as a good wire locator or buried cable locator.